Expanded polypropylene foam () products have gained widespread applications in various industries due to their excellent properties such as lightweight, high strength, and good thermal insulation. Here is a detailed introduction to the production process of EPP products.

Raw Material Preparation

High-quality polypropylene (PP) pellets are selected as the base material. This is crucial as it directly affects the quality of EPP foam products. In addition, auxiliary raw materials like blowing agents, catalysts, and stabilizers are prepared. Precise proportioning of these auxiliary materials is essential to ensure the quality of the final product.

Pretreatment

PP pellets need to be dried to remove moisture. Excess moisture can lead to the formation of bubbles during production, which may compromise the product's integrity. Meanwhile, the auxiliary raw materials are pre-mixed to ensure uniform distribution during the production process.

Melting and Extrusion

The dried PP pellets are melted through a melt extruder, forming molten PP. During this process, the pre-mixed auxiliary raw materials are added to the melt extruder to blend thoroughly with the PP.

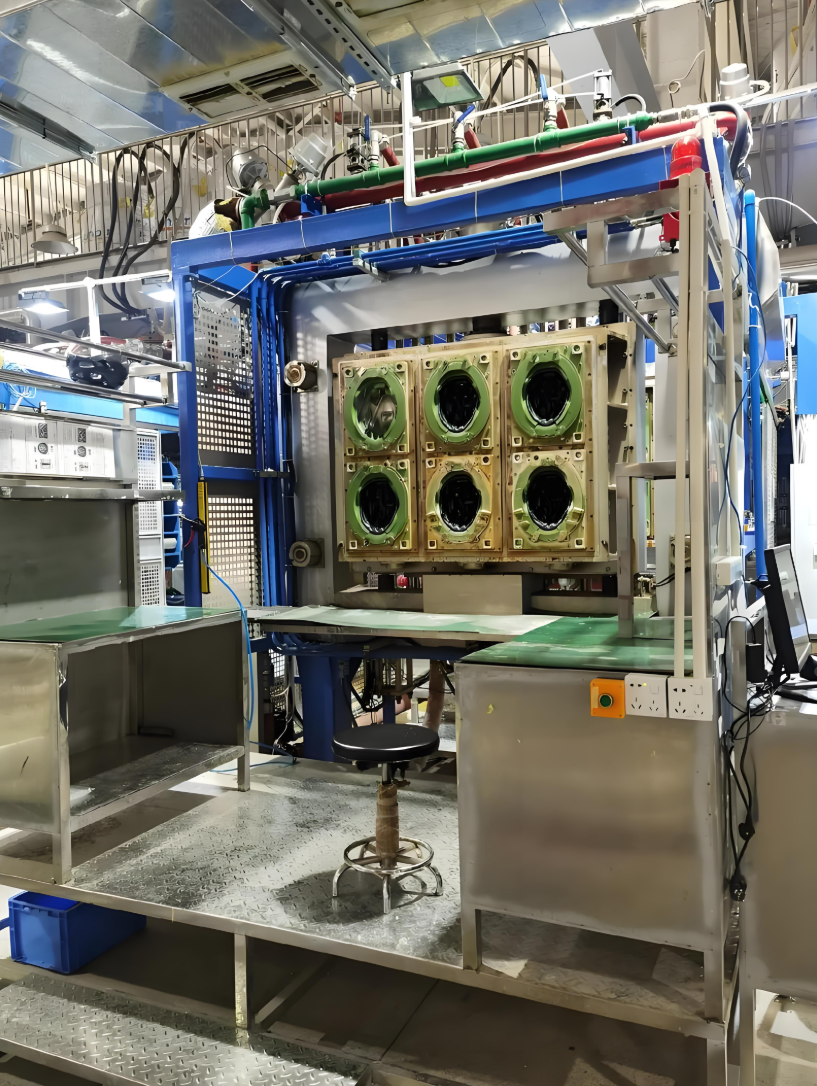

Foaming

As the molten PP is being extruded, the blowing agent comes into play, creating numerous bubbles within the molten PP. By controlling the amount and speed of the blowing agent addition, the density and cell structure of the EPP product can be adjusted precisely.

Cooling and Shaping

The foamed EPP foam material is cooled by a cooling device, which solidifies and shapes it. Adjusting the cooling speed and temperature is vital for achieving good dimensional stability and physical properties of the EPP product.

Cutting and Processing

After cooling and shaping, the EPP foam product is cut into the desired shape and size. Further processing, such as punching holes or slot-cutting, can be carried out according to customer requirements.

Inspection and Packaging

The cut EPP foam products are inspected for quality to meet relevant standards and customer demands. Qualified products are then packaged to prevent damage during transportation.

Warehousing and Storage

Packaged EPP foam products are stored in a suitable environment. Regular checks and maintenance are conducted to ensure the stability of their quality.

In conclusion, through this well-defined production process, high-quality EPP foam products can be manufactured to meet the diverse needs of different industries.

Expanded polypropylene foam () products have gained widespread applications in various industries due to their excellent properties such as lightweight, high strength, and good thermal insulation. Here is a detailed introduction to the production process of EPP products.

Raw Material Preparation

High-quality polypropylene (PP) pellets are selected as the base material. This is crucial as it directly affects the quality of EPP foam products. In addition, auxiliary raw materials like blowing agents, catalysts, and stabilizers are prepared. Precise proportioning of these auxiliary materials is essential to ensure the quality of the final product.

Pretreatment

PP pellets need to be dried to remove moisture. Excess moisture can lead to the formation of bubbles during production, which may compromise the product's integrity. Meanwhile, the auxiliary raw materials are pre-mixed to ensure uniform distribution during the production process.

Melting and Extrusion

The dried PP pellets are melted through a melt extruder, forming molten PP. During this process, the pre-mixed auxiliary raw materials are added to the melt extruder to blend thoroughly with the PP.

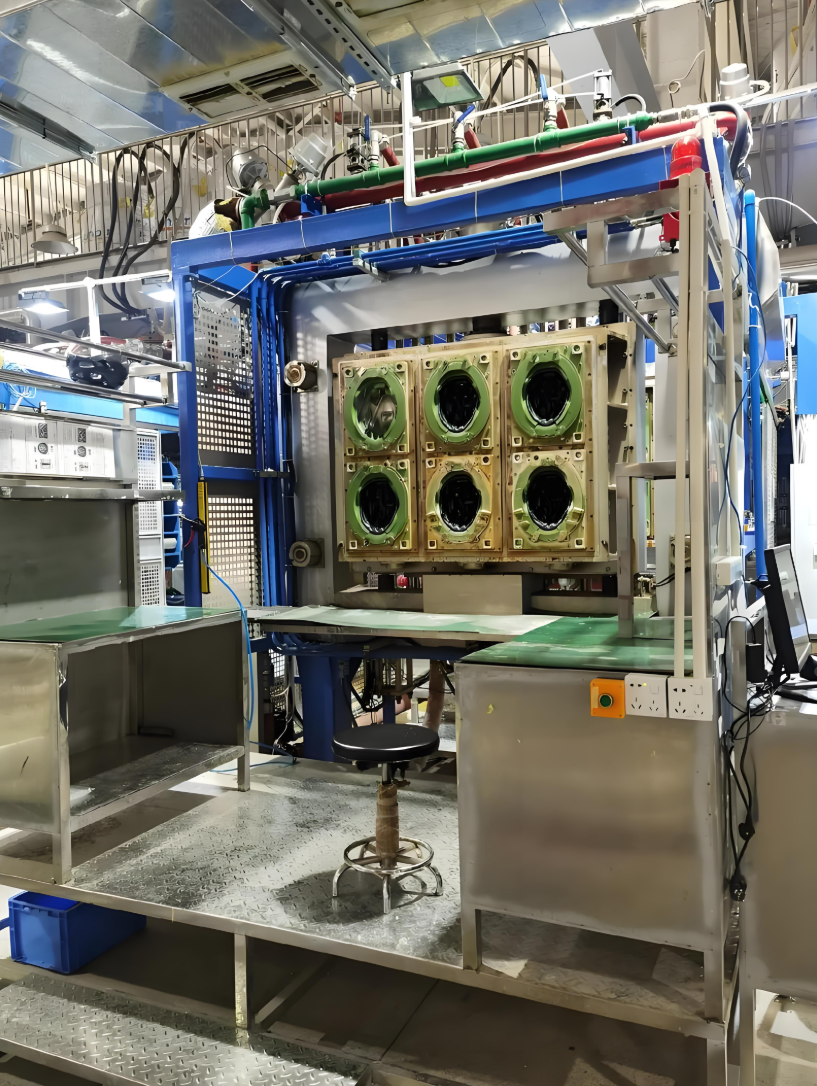

Foaming

As the molten PP is being extruded, the blowing agent comes into play, creating numerous bubbles within the molten PP. By controlling the amount and speed of the blowing agent addition, the density and cell structure of the EPP product can be adjusted precisely.

Cooling and Shaping

The foamed EPP foam material is cooled by a cooling device, which solidifies and shapes it. Adjusting the cooling speed and temperature is vital for achieving good dimensional stability and physical properties of the EPP product.

Cutting and Processing

After cooling and shaping, the EPP foam product is cut into the desired shape and size. Further processing, such as punching holes or slot-cutting, can be carried out according to customer requirements.

Inspection and Packaging

The cut EPP foam products are inspected for quality to meet relevant standards and customer demands. Qualified products are then packaged to prevent damage during transportation.

Warehousing and Storage

Packaged EPP foam products are stored in a suitable environment. Regular checks and maintenance are conducted to ensure the stability of their quality.

In conclusion, through this well-defined production process, high-quality EPP foam products can be manufactured to meet the diverse needs of different industries.