In the world of innovative materials, Expanded Polypropylene foam () has emerged as a star, and at Simingrui, we understand that the key to unlocking its full potential lies in our state - of - the - art EPP foam molds.

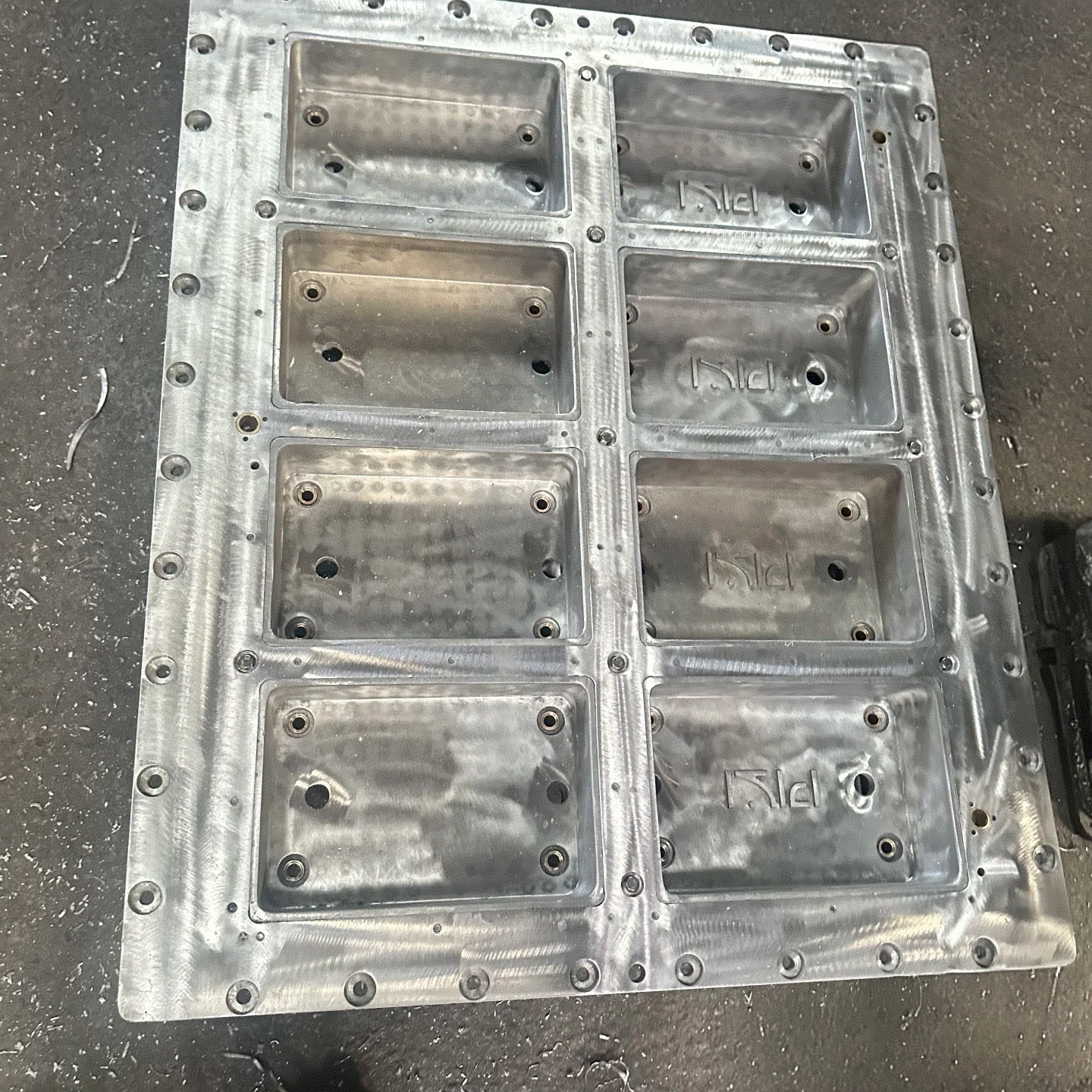

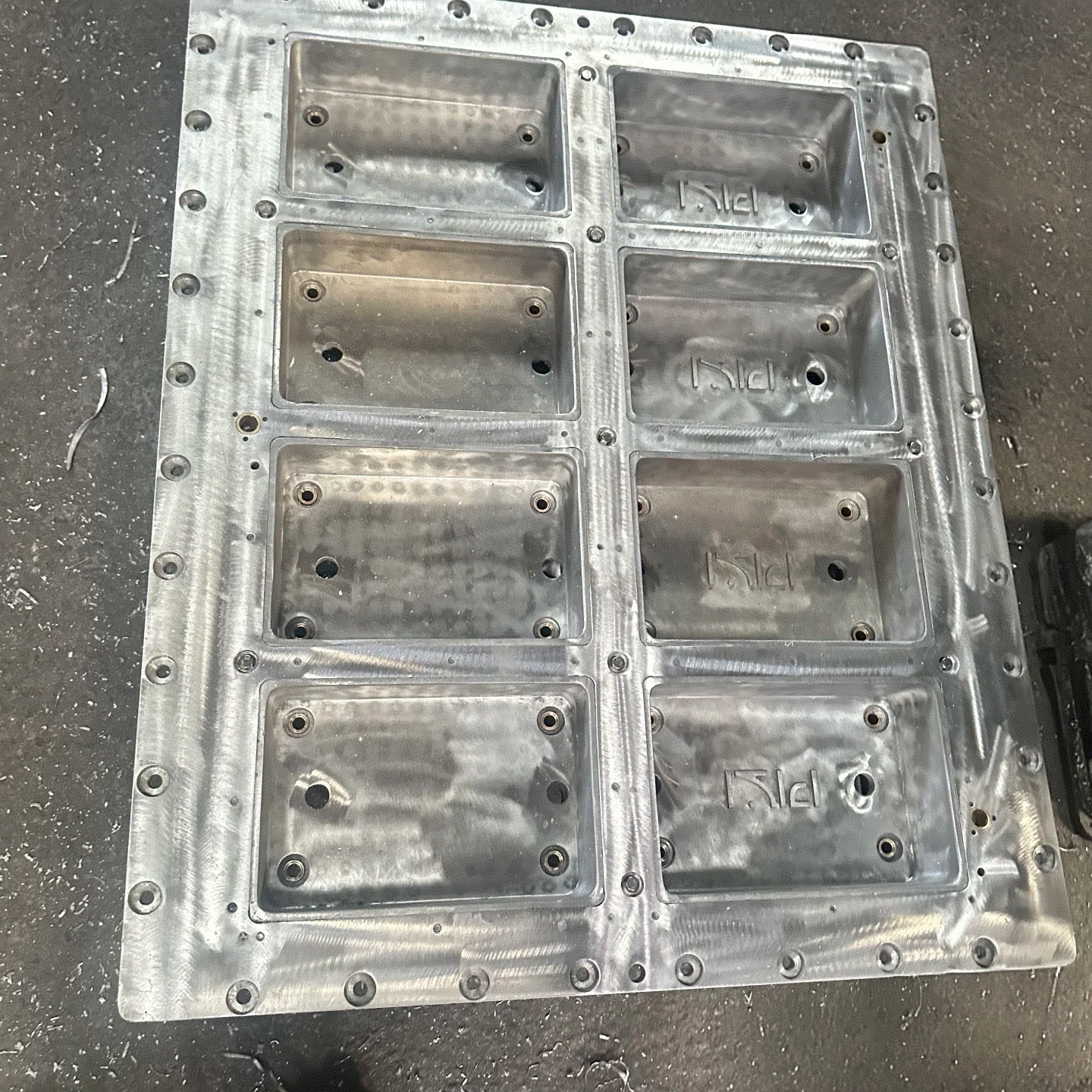

Our EPP foam molds are precision - engineered structures. The mold plates, including convex, concave, and back plates, form the core framework. Made from high - quality 5052/491 anti - rust aluminum plates, they ensure excellent fatigue resistance, plasticity, and corrosion resistance. The convex and concave struts, crafted from φ30 aluminum alloy rods, provide robust support, maintaining a stable structure during the molding process.

The working principle of our EPP foam molds is a fascinating process. First, EPP beads are pre - pressurized in a tank. Then, using compressed air, these beads are injected into the mold cavity. Steam is introduced next, causing the beads to expand and fuse together, forming the desired shape. After cooling and stabilization, the finished product is smoothly ejected by the ejector pins.

Material selection is crucial for our molds. We predominantly use pure aluminum alloys like 6061 and 7075. Aluminum's outstanding thermal conductivity allows for even heat distribution during the steam - molding stage, ensuring consistent quality of EPP products. Its lightweight nature also simplifies mold handling, while its superior machinability enables the creation of complex shapes to meet diverse customer needs.

Our EPP foam molds are widely applied across multiple industries. In the automotive sector, they produce components such as bumper cores and headrests, enhancing both vehicle safety and fuel efficiency. For the packaging industry, our molds create protective and eco - friendly packaging solutions for electronics, medical devices, and food products. Additionally, in the cold - chain and consumer goods markets, our EPP foam molds are used to manufacture insulated boxes, children's toys, and sports equipment.

At Simingrui, we are committed to continuous innovation in EPP foam mold technology. Our molds not only guarantee high - quality production but also contribute to the development of sustainable and high - performance EPP products. Explore our range of EPP foam molds and discover how we can transform your ideas into reality.

In the world of innovative materials, Expanded Polypropylene foam () has emerged as a star, and at Simingrui, we understand that the key to unlocking its full potential lies in our state - of - the - art EPP foam molds.

Our EPP foam molds are precision - engineered structures. The mold plates, including convex, concave, and back plates, form the core framework. Made from high - quality 5052/491 anti - rust aluminum plates, they ensure excellent fatigue resistance, plasticity, and corrosion resistance. The convex and concave struts, crafted from φ30 aluminum alloy rods, provide robust support, maintaining a stable structure during the molding process.

The working principle of our EPP foam molds is a fascinating process. First, EPP beads are pre - pressurized in a tank. Then, using compressed air, these beads are injected into the mold cavity. Steam is introduced next, causing the beads to expand and fuse together, forming the desired shape. After cooling and stabilization, the finished product is smoothly ejected by the ejector pins.

Material selection is crucial for our molds. We predominantly use pure aluminum alloys like 6061 and 7075. Aluminum's outstanding thermal conductivity allows for even heat distribution during the steam - molding stage, ensuring consistent quality of EPP products. Its lightweight nature also simplifies mold handling, while its superior machinability enables the creation of complex shapes to meet diverse customer needs.

Our EPP foam molds are widely applied across multiple industries. In the automotive sector, they produce components such as bumper cores and headrests, enhancing both vehicle safety and fuel efficiency. For the packaging industry, our molds create protective and eco - friendly packaging solutions for electronics, medical devices, and food products. Additionally, in the cold - chain and consumer goods markets, our EPP foam molds are used to manufacture insulated boxes, children's toys, and sports equipment.

At Simingrui, we are committed to continuous innovation in EPP foam mold technology. Our molds not only guarantee high - quality production but also contribute to the development of sustainable and high - performance EPP products. Explore our range of EPP foam molds and discover how we can transform your ideas into reality.