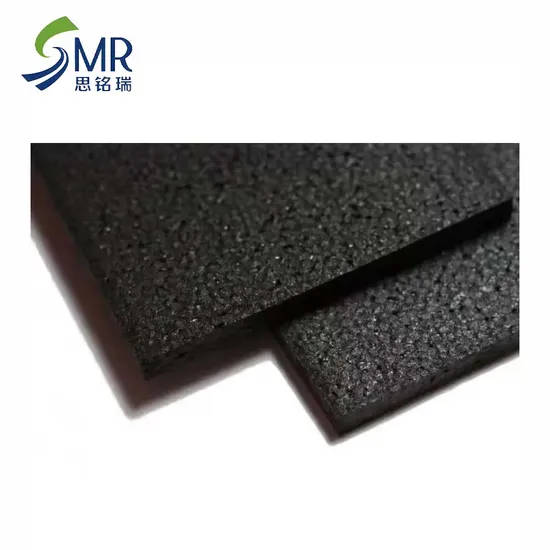

Expanded polypropylene (EPP) foam board, a versatile thermoplastic material, exhibits distinct morphological characteristics contingent upon its density, influencing its performance across various applications. At lower density, typically ranging from 15–30 kg/m³, EPP foam boards showcase a soft, lightweight structure with large, interconnected cells. This configuration renders them highly compressible, making them ideal for packaging delicate items, as the material can absorb significant impact forces while minimizing added weight.

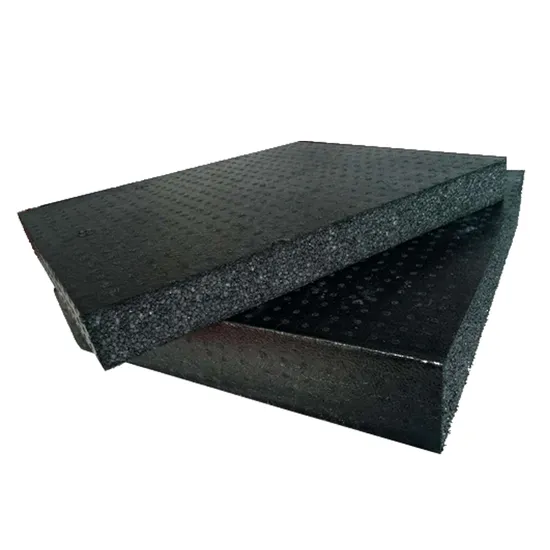

As epp foam density to the range of 30–60 kg/m³, EPP foam boards develop a more rigid and robust morphology. The cell structure becomes smaller and more uniform, enhancing mechanical strength and dimensional stability. These mid-density EPP boards find extensive use in automotive interior components, sports equipment, and construction insulation, where they provide reliable support and insulation while maintaining a favorable strength-to-weight ratio.

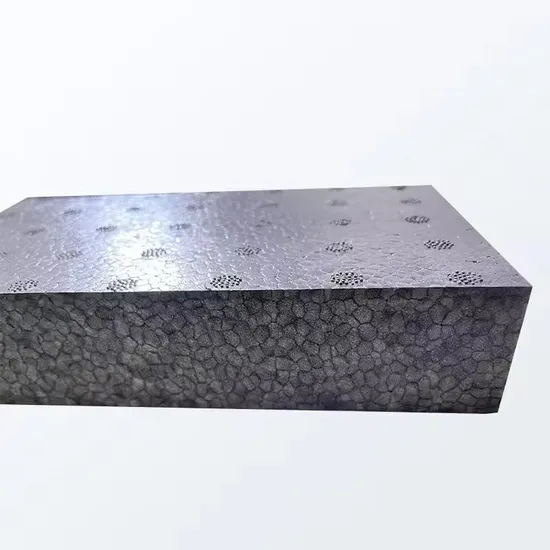

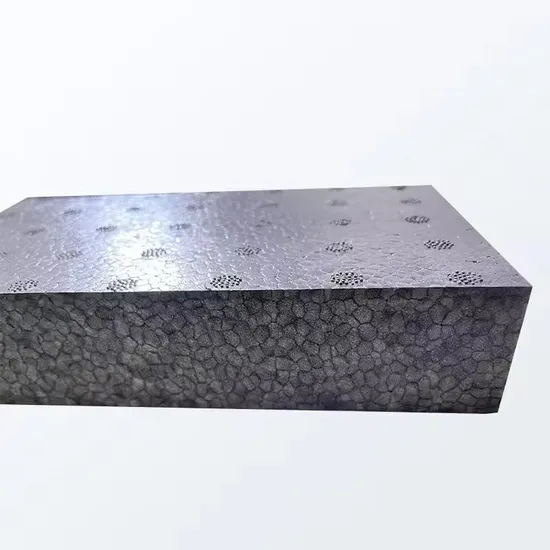

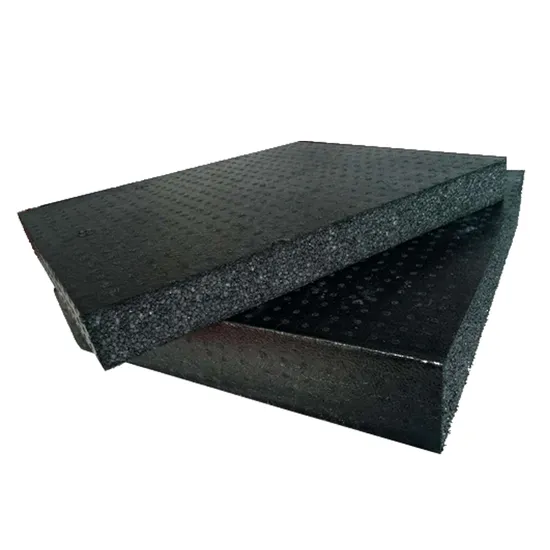

High EPP foam density boards, exceeding 60 kg/m³, feature a dense, compact cell structure, endowing them with exceptional load-bearing capabilities. Such boards are often employed in industrial applications, including load-bearing packaging, structural components, and high-performance insulation systems.

Simingrui's epp manufacturing production line represents a pinnacle of manufacturing technology, ensuring consistent quality and high efficiency. Leveraging advanced steam molding and extrusion techniques, the line precisely controls foam expansion and density, enabling the production of EPP boards tailored to diverse specifications. Its automated quality control systems guarantee uniformity in cell structure and density distribution, while intelligent energy management optimizes resource utilization. With Simingrui's production line, manufacturers can produce EPP foam boards that meet stringent international standards, catering to the evolving demands of global markets.

Expanded polypropylene (EPP) foam board, a versatile thermoplastic material, exhibits distinct morphological characteristics contingent upon its density, influencing its performance across various applications. At lower density, typically ranging from 15–30 kg/m³, EPP foam boards showcase a soft, lightweight structure with large, interconnected cells. This configuration renders them highly compressible, making them ideal for packaging delicate items, as the material can absorb significant impact forces while minimizing added weight.

As epp foam density to the range of 30–60 kg/m³, EPP foam boards develop a more rigid and robust morphology. The cell structure becomes smaller and more uniform, enhancing mechanical strength and dimensional stability. These mid-density EPP boards find extensive use in automotive interior components, sports equipment, and construction insulation, where they provide reliable support and insulation while maintaining a favorable strength-to-weight ratio.

High EPP foam density boards, exceeding 60 kg/m³, feature a dense, compact cell structure, endowing them with exceptional load-bearing capabilities. Such boards are often employed in industrial applications, including load-bearing packaging, structural components, and high-performance insulation systems.

Simingrui's epp manufacturing production line represents a pinnacle of manufacturing technology, ensuring consistent quality and high efficiency. Leveraging advanced steam molding and extrusion techniques, the line precisely controls foam expansion and density, enabling the production of EPP boards tailored to diverse specifications. Its automated quality control systems guarantee uniformity in cell structure and density distribution, while intelligent energy management optimizes resource utilization. With Simingrui's production line, manufacturers can produce EPP foam boards that meet stringent international standards, catering to the evolving demands of global markets.